Introduction

This guide helps you create a Standard Operating Procedure (SOP).

Complete Step 1-Chemical Hygiene Plan (CHP) first. You will need information on your CHP to complete this.

You might want to check if the SOP for your process already exists in the Digital Commons.

Make sure you download the three-page Chemical Hygiene Plan file from Introducation-Chemical Hygiene Plan and open it in Adobe Acrobat or Acrobat Reader. The file is an interactive PDF and will not function properly in a browser.

-

-

Download the Chemical Hygiene Plan file. The SOP is page 3.

-

Open the file in Adobe Acrobat.

-

The file will not function in browsers.

-

-

-

Your name will be automatically carried over from your entries on page 1.

-

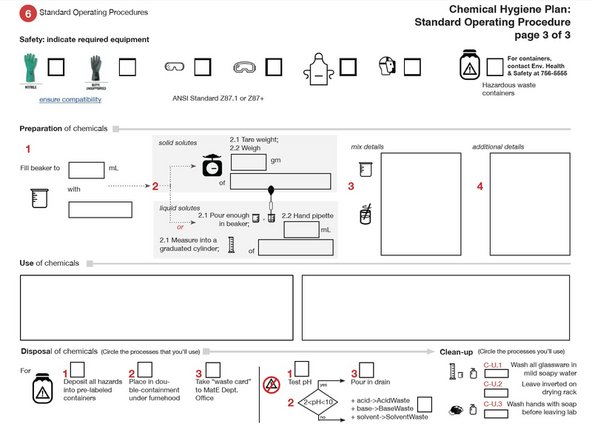

Check the type of gloves needed. Visit this site if needed.

-

Nitrile: Offers chemical and abrasion resistance, and is a very good general-duty material. Also provides protection from oils, greases, petroleum products and some acids and caustics.

-

Butyl: Offers the highest permeation resistance to gas and water vapors. Especially suited for use with esters and ketones.

-

Severe injury or death can result if gloves do not provide protection.

-

Indicate remaining equipment needs.

-

41-203 and 191-212 have existing Haz Waste receptacles for Acids, Bases and Solvents beneath the fume hoods; Indicate only the additional receptacles needed.

-

-

-

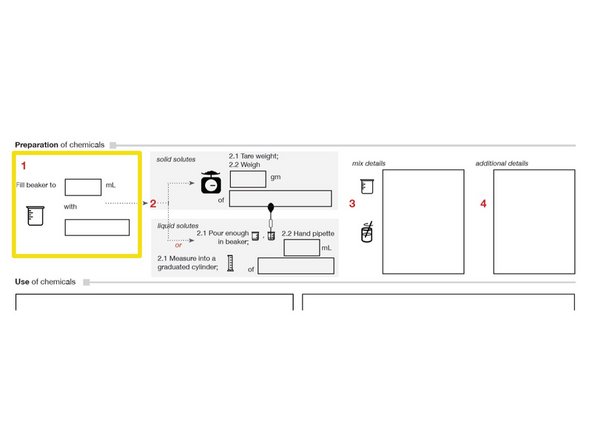

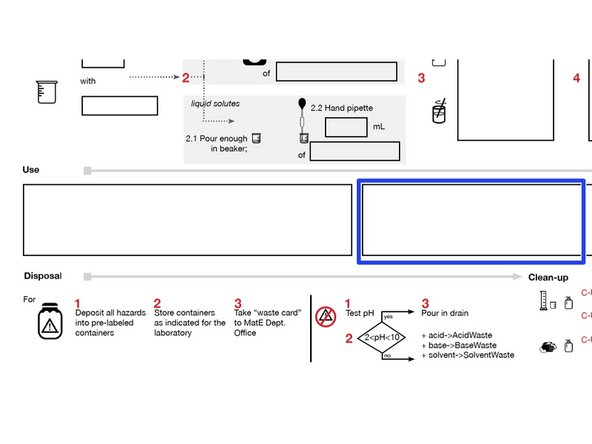

Indicate the volume and type of solvent to place into a beaker (e.g, water).

-

Minimize volumes of reagents by using the least amount needed. Generally, remaining volumes will become waste.

-

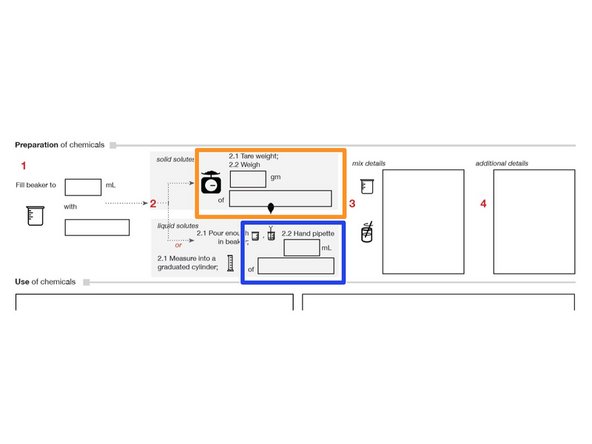

For solids, indicate the amount to be measured.

-

For measuring solids, use filter paper or a plastic tray to avoid contaminating the scale.

-

For liquids, indicate the amount to be measured.

-

Graduated cylinders may be used instead of pipettes.

-

Never use your mouth to pipette chemicals.

-

-

-

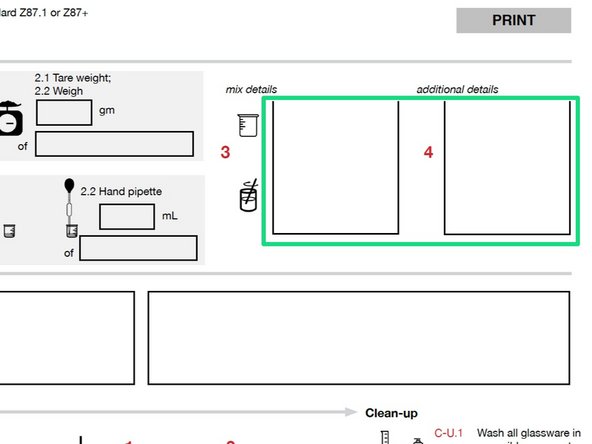

Indicate the remaining chemical steps by typing in the text boxes.

-

If your process uses more than one solvent or solution, you can type the steps in these text boxes.

-

Use these text boxes to indicate processes such as automatic stirring, duration of stirring, heating, heating temperature or other specific needs.

-

Indicate special handling instructions here.

-

e.g., HAZARDOUS powders should be weighed inside a fume hood with filter paper that becomes HAZARDOUS waste.

-

-

-

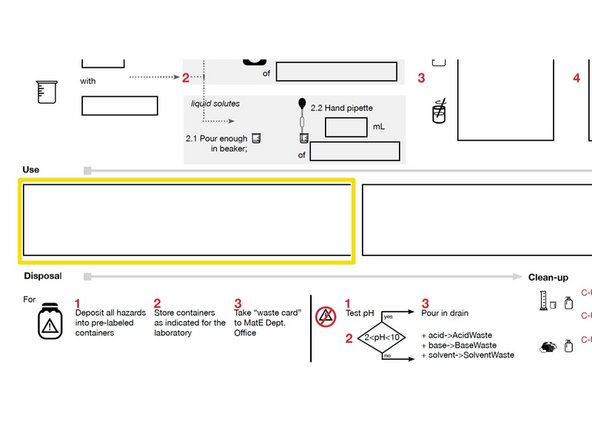

State the procedure for using the chemicals, numbering each step with "U1", "U2", "U3", ...

-

Use additional box if needed.

-

-

-

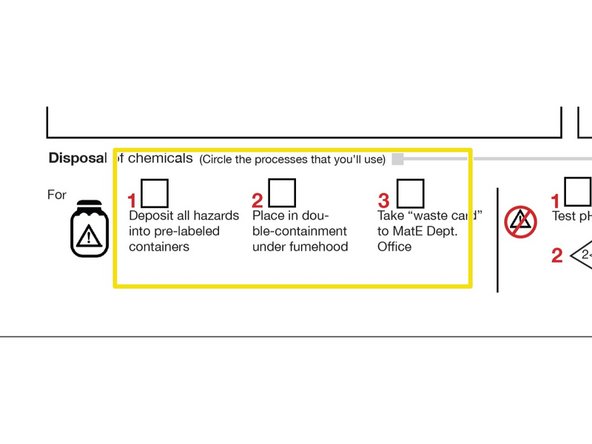

For Hazardous Waste, check the steps that need to be followed.

-

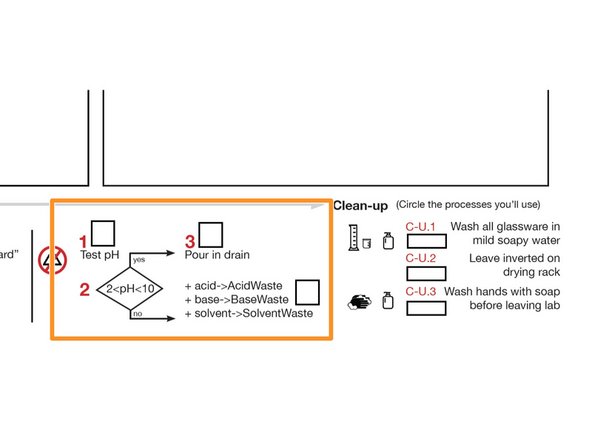

For non-Hazardous, check the steps that need to be followed.

-

-

-

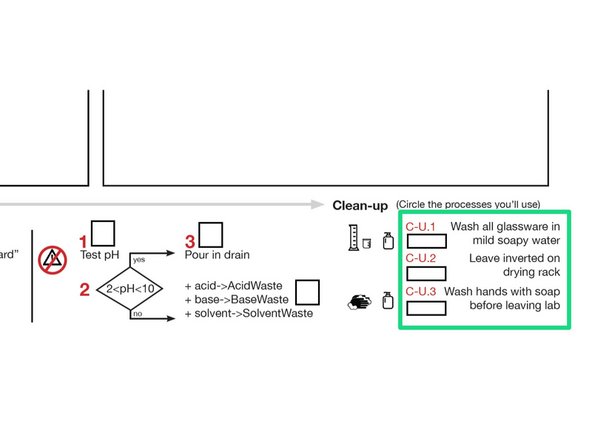

Check the clean up steps that need to be followed.

-

-

-

Save and electronic version of this file and print a hard copy for yourself.

-

Submit your the electronic version of your Chemical Hygiene Plan, this SOP and URL links to your Materials Data Sheets to MatE Faculty Safety Facilitator.

-

-

Allow 1 week for review of the plan.

-

After you receive an approved version of your CHP and SOP, you are safety-ready to conduct your experiment.

-

You can proceed to B3-Experimental Setup.

-

You are now ready to submit your Chemical Hygiene Plan and Standard Operating Procedures for approval to the Materials Engineering Faculty Safety Facilitator.

When you receive approval, complete B3-How to set up your experiment.

The MatE Faculty Safety Facilitator is currently lvanasup@calpoly.edu

You are now ready to submit your Chemical Hygiene Plan and Standard Operating Procedures for approval to the Materials Engineering Faculty Safety Facilitator.

When you receive approval, complete B3-How to set up your experiment.

The MatE Faculty Safety Facilitator is currently lvanasup@calpoly.edu

Cancel: I did not complete this guide.

27 other people completed this guide.