Introduction

Hardness testing, while somewhat simple, requires the proper selection of test type to yield relevant results. This section goes though the theory of hardness testing, test type and the interpretation of the results.The attached documents help show: the connection between standards and hardness tests;the test conditions for each scale.

-

-

There are two types of Rockwell tests: Rockwell and superficial Rockwell. Rockwell uses a minor load of 10 kgf; major load of 60, 100, or 150 kgf. Superficial uses minor load of 3 kgf; major loads are 15, 30, or 45 kgf.

-

The type of Rockwell Hardness (RH) test is indicated with a letter designation

-

A fourth letter indicates the type of indenter: stainless steel (S); carbide (W).

-

Superficial tests are indicated with a number, which indicates the major load in kg force. This shows a superficial Rockwell Hardness N scale with 30 kg force as a major load.

-

RH values are usually reported to one decimal place.

-

-

-

In the Rockwell hardness test, an indenter first applies a minor load to the sample surface, shown here as a cross-hatched section.

-

The major load is then applied and released.

-

The difference in indenter tip depth between the two loads is the basis for computing the Rockwell hardness. Softer materials will have a larger depth when the major load is applied.

-

The indenter may be either a diamond cone or a hardened ball depending principally on the characteristics of the material being tested.

-

-

-

Choosing a Rockwell scale is based on four factors: material, test location, specimen or hardened layer thickness and scale limitations.

-

Material: Use a diamond indenter for hard materials (carbide or steel) and one of 6 scales: Rockwell C, A, D, 45N, 30N, or 15N.

-

Chose a scale that will provide the best accuracy, sensitivity, and repeatability. Typically, as the thickness of the sample decreases the major load should also decrease.

-

The thickness of the layer that is tested should be a minimum of 10 times the indentation thickness.

-

The ASM Handbook Online provides equations that can be used to calculate minimum depths.

-

Test location: Tests should be at least 2.5 indentation diameters away from an edge to get accurate readings.

-

Adjacent hardness measurements should be spaced by 3 indentation diameters.

-

You can download a table of all test conditions and ASTM standards that apply.

-

-

-

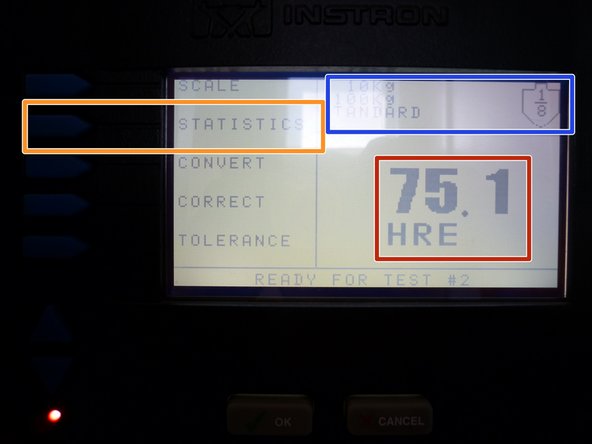

The Rockwell hardness reading will be displayed along with the scale.

-

As with any measurement, there is natural variation in the readings. The statistics function can be used to record variation.

-

If using the statistics function, you need to clear the values before taking the first measurement.

-

Press the STATISTICS button and follow instructions for clearing the values.

-

The load and indenter types are also displayed.

-

Indenters can be manually changed. Make sure that the machine has the appropriate indenter. The reading will be inaccurate if the indenter is not correct.

-